Time & motion studies – The key to improving efficiency

Time & motion studies can unearth a lot of issues that you otherwise would not have spotted on your shop floor. According to this great article on time & motion studies, timed task analysis traces its roots back to the 1880s. Motion analysis dates back to World War I studies of the precise movements involved in assembling and disassembling small arms. By the 1950s, industry had widely combined the two types of analysis and adopted time & motion studies across major industries.

So, what does it take to achieve efficiency on the production floor? In our view, it is the ability to question each and every process that is being followed currently. Even thinking about doing a small daily task differently can improve the entire process chain.

So how does it all happen? Here’s our guide to time & motion studies.

1. Record everything

It is critical to observe and record every single process on the production floor without bias in order for the time & motion study to be useful.

2. Map the process

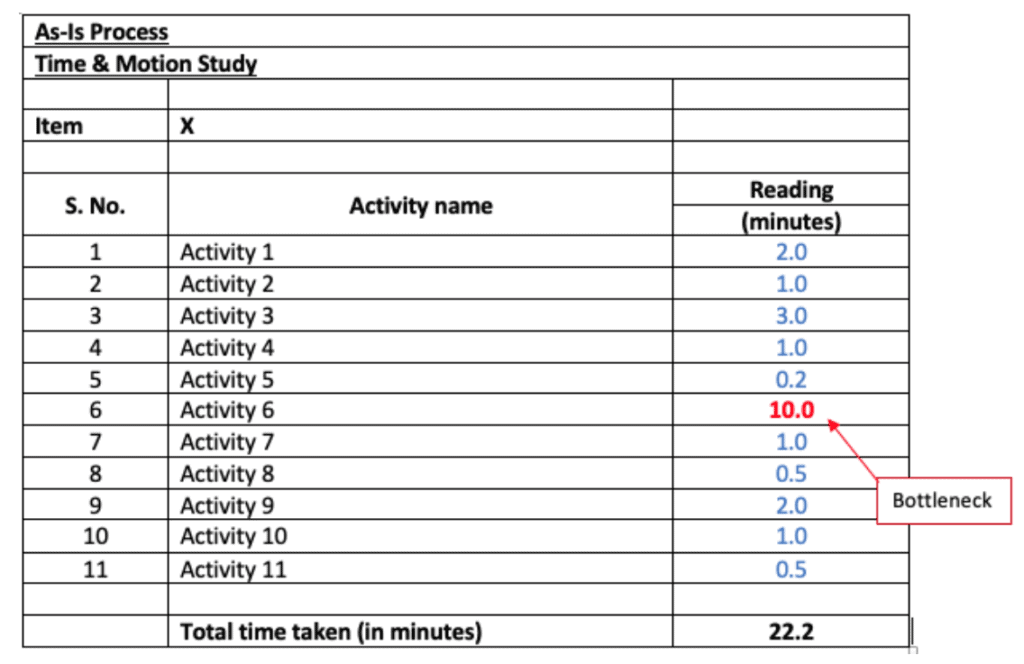

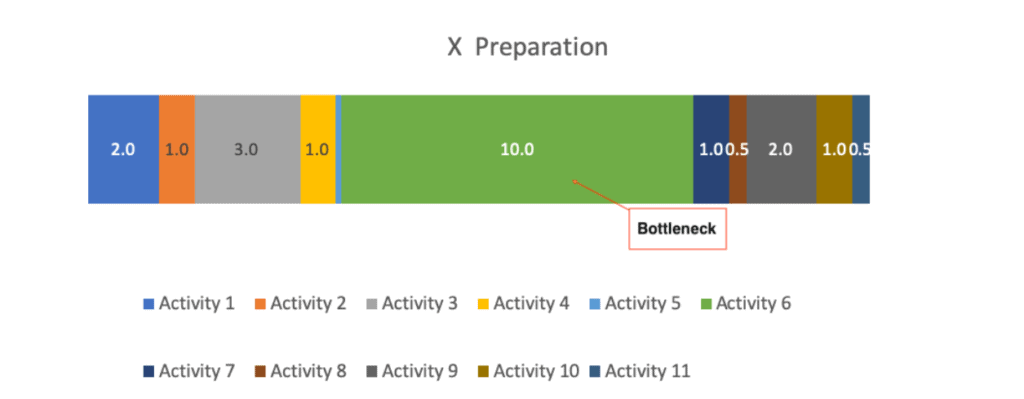

Observe and map the entire as-is (or current) process by breaking down each activity to smaller tasks and noting the times that it takes for each task. We then end up with a total cycle time.

To reduce the cycle time, a closer look at each of the processes and their respective times is a must to determine the bottleneck.

A bottleneck is one process in a chain of processes, such that its limited capacity reduces the capacity of the whole chain. The result of having a major bottleneck are delays in production, supply overstock, pressure from customers and low employee morale.

3. Manage bottlenecks

The study above helped us identify the bottlenecks. So how does one manage them?

Once you know the time it takes to produce the different products, which stations they come off of and which specific pieces of equipment they come from, then you can allocate the right amount of labor to those stations. If you have a product that takes longer than others, you ask yourself whether you can eliminate wasted steps or add labor to reduce production time.

Specifically in food manufacturing, there are many ways to fix things by redistributing tasks. According to Foodservice Equipment Reports, say we have two people making sandwiches: one doing tops and one doing bottoms. Maybe we’ll find that if the first person puts the cheese on instead of the second person, the work will be balanced out and the process will flow more quickly.

If those kinds of changes aren’t sufficient, then aspects such as investing in a new fryer or new grill could be explored. If we redesign some aspect, e.g. we can switch to using designated areas for tools close to the work area instead of unnecessary movement on the production floor.

Other ways to manage bottlenecks include minimizing downtime, set-up time, changeover time and removing non-value added activities done by the bottlenecks or resources. The advantage of reducing the bottlenecks is increased efficiency, reduced costs and customer satisfaction.

What issues does your shop floor face?

- Process lines not balanced

- Operators idle, waiting for activities

- End-to-end production taking too long

- Not meeting customer delivery deadlines

Does this seem familiar? If so, we at AND can help you solve these challenges and make your shop floor an efficient one. Get in touch with us, the foremost management & business consultants in Hyderabad.